High Precision Lapping Processes with ISOLAP

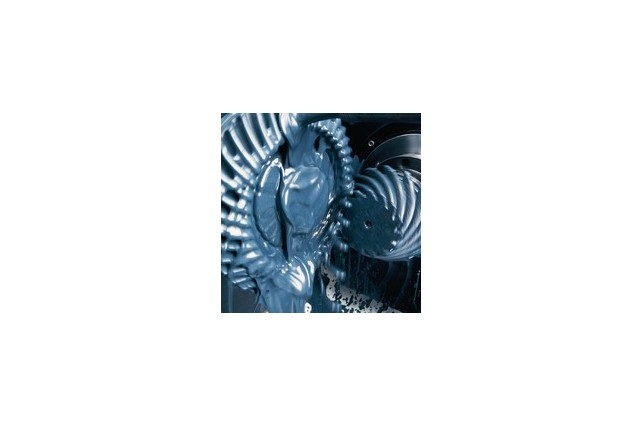

Lapping can be used to obtain a specific surface roughness of components. It is also used to obtain very accurate surfaces. Lapping is a machining process, in which two surfaces are rubbed together with an abrasive (e.g. silicon carbide or corundum) between them. The abrasive is usually dispersed in a fluid, this mixture is called slurry. The lapping process is commonly used to optimize the surface roughness of bevel gears, hypoid gears, injection nozzles and gear pumps.

PETROFER has offered fluids for the lapping process for many years. We provide amongst others a thixotropic lapping fluid without lapping grit: ISOLAP 6937. The customer can add his grit, for example Silicon carbide F 240. ISOLAP 6937 provides an absolutely stable slurry, the grit (abrasive) does not sag or drop out of suspension. Furthermore PETROFER offers ready-made lapping mixtures for direct application, e.g. ISOLAP SC 220, ISOLAP DC 207/240 and ISOLAP SC 320. These thixotropic lapping fluids contain different types of grit in different quantities. DAF in the Netherlands uses ISOLAP SC 220 (contains 30% SiC F220) on a KLINGELNBERG lapping machine for machining of bevel gears. GKN in Sweden used in past ISOLAP SC 320 (contains 35% SiC F320), but shortly they want to test ISOLAP SC 240 (with 35% SiC F240) to reduce the process flow. They use ISOLAP e.g. for lapping bevel gears for the rear axle. DAIMLER in Germany uses ISOLAP 6937 (fluid without grit) and ISOLAP DC 207/240 (contains 70% SiC F240). Other customers are e.g. MAN Trucks, BMW, Mahle and several manufacturers of gears and transmissions.

For further data and to arrange trials please contact Petrofer UK PLC; e-mail: enquiries@petrofer.co.uk or telephone: 01952 580 100.

Thomas Sobotta, R+D 1 (contact: sobotta@petrofer.com)

Back